The annual SEKISUI KAIZEN Convention took place this year in January for the 52nd time. Together with global companions, the winner of the latest European KAIZEN convention presented his project in Kyoto, Japan.

As every year, SEKISUI CHEMICAL CO., LTD. invited KAIZEN representatives from all over the world to the Global KAIZEN Convention. Teams from Japan, North America/Mexico, China, Europe and the Asia-Pacific region accepted the invitation and met on 19th of January 2018 in Kyoto, Japan.

13 teams from SEKISUI companies worldwide

A total of 13 teams took part in this year’s Global KAIZEN Convention to present their KAIZEN activities and exchange information as well as ideas. Originally, KAIZEN originates from the Japanese production culture. SEKISUI has set itself the goal of creating a corporate culture of daily improvement in order to increase the growth of each individual working in the factory building or office.

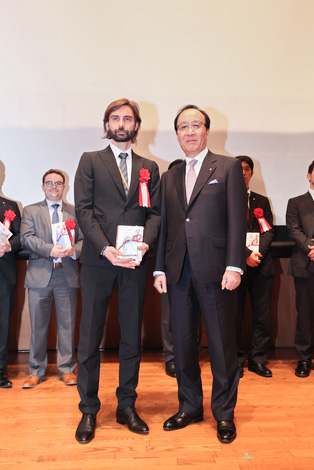

President Koge opened the Global KAIZEN Convention

SEKISUI President Teiji Koge opened the event with an introductory speech. According to him, the presidents of the three divisions – Housing Company, Urban Infrastructure, Environmental Products Company & High Performance Plastics Company – welcomed the participants.

The European representative: Manuel Rivero

Manuel Rivero from Sekisui Specialty Chemicals Europe and his team won at the 7th European KAIZEN Convention, which took place last year in Düsseldorf, Germany. As a reward, Manuel was allowed to present their KAIZEN idea in Japan to an international audience.

The winners of this year’s Global KAIZEN Convention

Unfortunately, the European project did not reach the podium. Nevertheless, it was a very enriching experience and a great opportunity for Manuel to get in touch with SEKISUI employees from all over the world.

The jury chose the following three winners: The third place went to the “SBS” team from Tokuyama Sekisui Industry Co., Ltd. for their challenge to completely eliminate unstoppered tube defects at the SAP2 line. The second place was awarded to “Team Harada-denki” from Kyusyu Sekisui Industry Co., Ltd. Their project dealt with the question how a 100% nonadjusted rate for polyethylene pipe fusion can be achieved.

Last but not least: The team “Metabolism” from Sekisui Chemical Co., Ltd. Shiga (Minakuchi Plant) was at the top of the podium. They presented their findings about reducing variations of solder ACP(SAP) process inspections.

Congratulations to the winners for their great work and fantastic ideas!