The SPR™ process is used all around the world to rehabilitate challenging pipe profiles. Last year, the European team has managed an exciting project in Reichenbach. An outdated culvert below a transformer station had to be renewed under the most difficult conditions.

“Reichenbach im Vogtland” is a small town in Germany, where the Raumbach creek runs along the main street which leads into and out of the city. In 2014, the local energy company Envia noticed that a culvert, which lies under the transformer station of the company, was in need of renovation. The statics of the passage were outdated, the safety of the trasformer station no longer guaranteed. However, the renovation was critical because of very high requirements due to flood protection.

Envia commissioned SEKISUI Pipe Renewal B.V. based in Roermond to rehabilitate the culvert under the transformer station. The team is used to carry out refurbishment processes under extreme conditions. But in Reichenbach, the specialists had to challenge several limiting conditions in addition to the flood protection:

- The object was very difficult to reach.

- The culvert itself has extraordinary dimensions: it is no straight pass, but it is sharply curved and runs over 66 m with a small radius of almost 17 m.

- It is not a round diameter but a mouth profile with a height of 3.36m and a width of 3.85m.

- The creek cannot be diverted and so the rehabilitation has to be at dry weather flow.

- There are time restrictions since a protected fish spawns in this area. The renovation can only take place at a certain time of the year.

- Most critical for the client was that the maximum drainage cross section after the renovation should be about 6m2.

However, Envia decided to work with SEKISUI even because of these difficult conditions. Since only the SPR™ spiral wound trenchless method can manage all of these challenges. The SPR™ process can not only renew long and round profiles, but also works with such extreme dimensions.

Step 1: Inspection & calibration of the old pipe

Before the renovation could start, the creek run had to be scanned in detail. The team made it through the difficult entry and scanned the entire old profile using the 3D laser scan. This measures the exact cross section which allows to design the optimal SPR™ liner and materials. In Reichenbach they used 5 coils 79SW and 8 coils FW which were manufactured in Roermond. The most important part of the preparations was the introduction of the steel reinforcement.

Step 2: The winding process

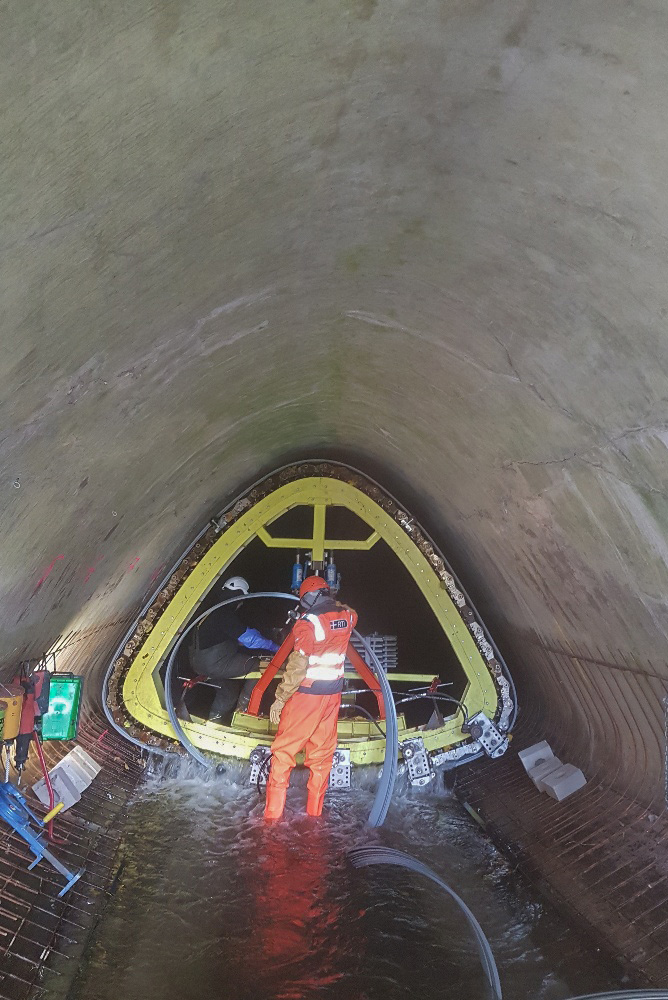

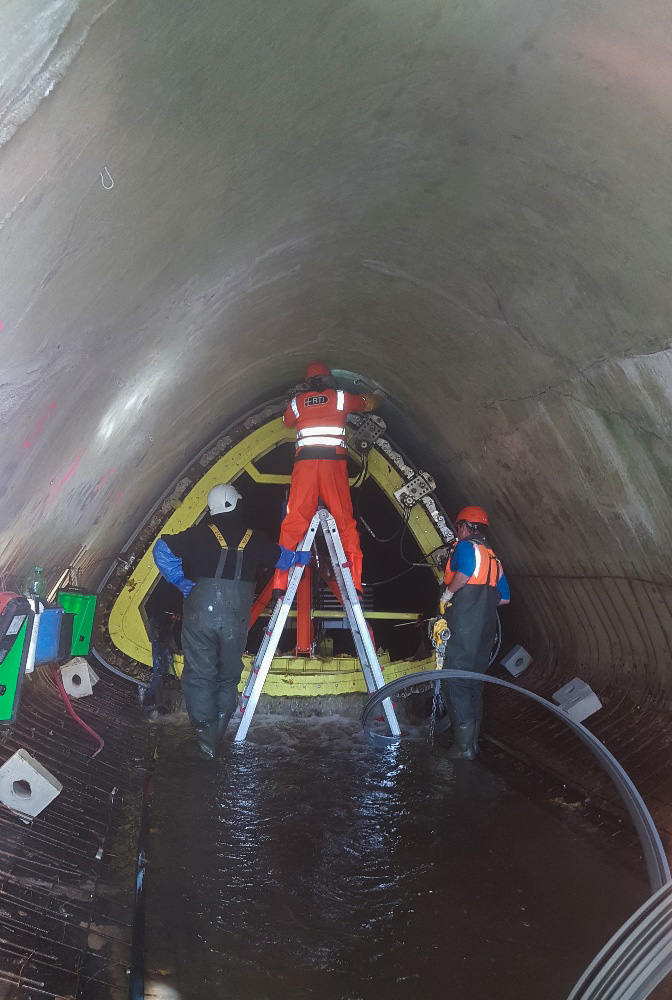

The construction site was set up quickly and safely and disrupted the main road in Reichenbach at no time. Neither pipes nor large vehicles had to be stored at the construction site. The winding process itself took about 3 weeks due to the challenging conditions. Inside the culvert, the SPR ™ profile was winded by the winding machine to the requested form and the PVC strips were interlocked to form a new watertight liner.

The winding machine enters the culvert.

The winding machine at work.

The winding machine at work.

It was a very difficult project for the team.

It was a very difficult project for the team.

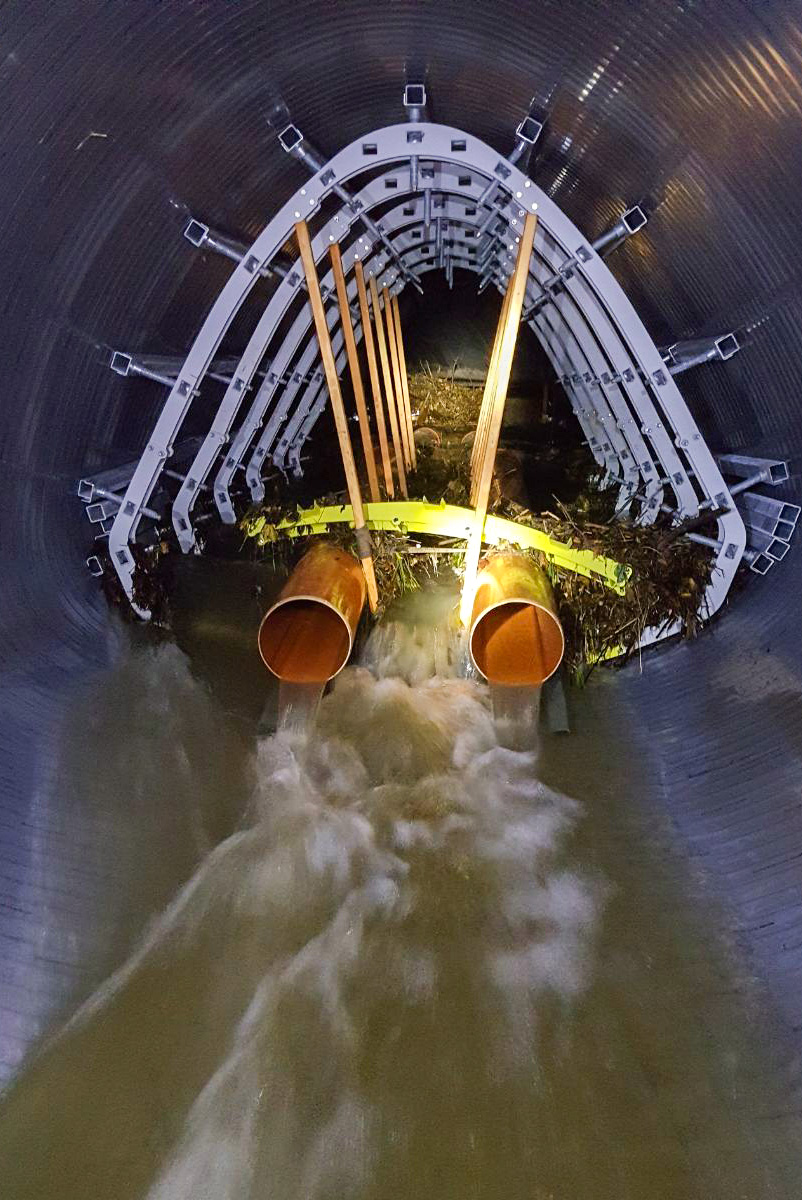

Step 3: Bracing system

After the winding process was completed, the bracing system was installed to protect the liner against uncontrolled buoyancy and deformation. The bracing system positions the SPR™ liner in the host pipe according to engineering specifications and thus ensures the appropriate wall thicknesses.

Step 4: Grouting

The last step of the complex process was the injection of a special high strength grout into the defined annular space between the host pipe and the spirally wound PVC profile. It is important to work only with highly flowable and high-strength grouting – in this case ca. 220 tons of mortar were used.

At least the bracing system was dismantled and the rehabilitated pipe was ready for service. The specialists of SEKISUI Pipe Renewal were very happy how smooth the operation was done: “We are used to work under strong conditions, but Reichenbach was really a challenging task. We are so proud that we could renew the culvert and the creek has a new and stable pipe. Thanks to our unique method the new pipe is so stable that you don’t need not worry about it over the next few years.” said Jens Vergin, Engineer from SEKISUI Pipe Renewal B.V..

The result: A complete new pipeline for Reichenbach.

The result: A complete new pipeline for Reichenbach.

The result: A complete new pipeline for Reichenbach.

Trenchless pipe renewal: A fast and secure rehabilitation procedure

Look at the video on the company website to see how the procedure works: https://sekisuispr.com/technology/gravity-solutions/spr/

The strength of the liner is usually out of the high performance grout material due to this the liner can be adapted according to all requirements. The SPR™ process is unique as it can provide a customized structural solution to aging pipelines. It can be engineered to correct hydraulic anomalies as well as restore the slope of the original pipe. The interlocking edges of the profile create an impermeable mechanical lock that can withstand strong deformational forces. SPR™ profile liners have been tested in accordance with industry standards and meet or exceed the standards for machine spiral-wound liners, ASTM F 1697 and ASTM F 1741. It is also DIBt approved.