In the beginning of 2019, SEKISUI in Europe celebrated the ground-breaking ceremony for the new plant of SEKISUI POLYMATECH EUROPE B.V.. As the plant operations are planned to start at the beginning of 2020, we would like to take a closer look at SEKISUI POLYMATECH EUROPE B.V. as a new member of SEKISUI in Europe, and one of its products: CGW® 2-humoral silicone heat radiation grease.

SEKISUI POLYMATECH EUROPE B.V. (hereafter SEKISUI POLYMATECH) will offer a variety of different products to original equipment manufacturers (OEMs) and Tier 1 suppliers (manufacturers who provides products directly to a company). At the beginning, the company will focus on customized products in the business field of thermal interface materials. At the same time, the team will get familiar with the European market – continuously looking for possibilities to distribute SEKISUI POLYMATECH products from the worldwide portfolio* as well as new developments and innovations depending on the demand.

What are thermal interface materials?

Thermal interface materials are materials that are inserted between two components in order to enhance the thermal coupling between them. A common use is heat dissipation, meaning when the thermal interface material is inserted as protection between a heat-producing device and a heat-dissipating device. SEKISUI POLYMATECH in the Netherlands will produce a range of both sheet-type and grease-type thermal interface materials for this usage.

One area that requires thermal interface materials: environmental-friendly vehicles. There are great hopes that electric vehicles (EVs) and plug-in hybrid vehicles (PHVs) will lead to reductions in CO2 emissions and mitigate global warming. Large-scale lithium-ion batteries (LiBs) that store electricity are fitted to the underside of these vehicles. However, the batteries generate huge amounts of heat, and unless this heat can be efficiently released, the performance of the batteries drops and can lead to failure.

This is the reason why the demand for thermal interface materials is rising, also for one of SEKISUI POLYMATECH’s products: CGW® 2-part heat radiation grease.

SEKISUI POLYMATECH products contribute to reduction of CO2 emissions when used in environment-friendly vehicles.

Grease-type thermal interface material.

Sheet-type thermal interface material.

CGW® 2-humoral silicone heat radiation grease

CGW® 2-humoral silicone heat radiation grease is a thermal interface material by SEKISUI POLYMATECH that is indispensable in environment-friendly vehicles and offers numerous advantages.

CGW® 2-humoral silicone heat radiation grease is supplied in the form of two unmixed liquids, two types of heat radiation compounds that contain thermal conductive fillers, sold as a primary and curative agent set. The transport can be done in drum cans and other reusable containers – particularly welcomed by customers in Europe where regulations are strict and environmental awareness is high. Later, the product is mixed and applied by the customer himself during the manufacturing process. After being mixed, CGW® stiffens at room-temperature, without the need for heating equipment (which uses energy).

CGW® can also be used as a cushioning material to protect the batteries. While “usual” heat release sheets become brittle when the heat radiation performance increases, CGW® retains its cushioning properties after it hardens.

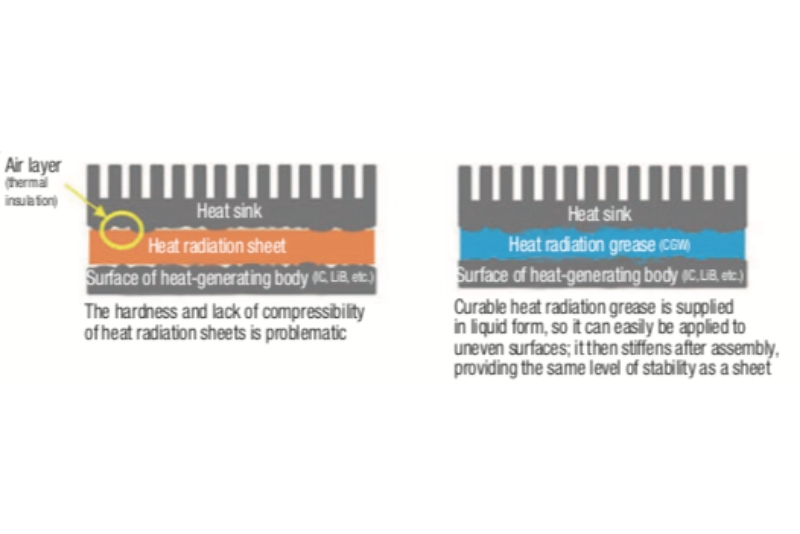

Moreover, SEKISUI POLYMATECH’s heat radiation grease is more compressible than heat radiation sheets what makes it suitable for application to the uneven undersides of vehicles.

Heat radiation sheets vs. heat radiation grease.

SEKISUI POLYMATECH’s CGW® 2-humoral silicone heat radiation grease offers many advantages and environment contributing aspects. SEKISUI POLYMATECH is confident that demand for the grease will grow and is looking forward to the production start at the new plant in Roermond.

*If you you are curious about other SEKISUI POLYMATECH products, you can learn even more on their website: https://www.polymatech.co.jp/english/products.html